Detail Infomation For Blow Molding Machine

Taizhou Fupusi Machinery Co. Ltd. is a company specializing in the manufacturing of blow machines that could produce plastic bottles and containers for mineral water, edible oil, soda, wine, cosmetics, lotion, detergent, pharmaceuticals, pesticides, food cans, daily chemicals, hot filling beverages, and other fields industries for more than 15 years in China, we also for customers whole plant equipment layout, to provide advisory services and technical support.

After our extensive in the field of PET blow machines semi-automatic, fully automatic, and blow molds so on, We started to help other companies and individuals interested to set up their new business in plastics. We provide guidance to source, set up, and run your plastic business. We supply the above machines and molds.

John Tao as the Owner/General Manager of Taizhou Fupusi Machinery Co., Ltd., who has more than 15 years of experience in the plastic bottle industry field, is focused on improving the quality of the machines and the after-sales system

- Ensuring machines operate stably and durably with simple operation

- Minimizing failure rates through rigorous quality control

- Prioritizing after-sales personnel training for seamless customer support

- Providing worry-free solutions with prompt issue resolution

- Delivering comprehensive post-purchase care to eliminate customer concerns

Welcome you come to our company for a visit, we will provide high-quality products and the best service for you.

Our blow machines has included 3 series, S-series, H-series and F-series.

S Series is semi auto blow machines

It can produce different shapes of bottles from 50ml to 30L, for mineral water, edible oil, soda, wine, cosmetics, lotion, detergent, pharmaceutical, pesticide, food cans, daily chemical, hot filling beverage and other fields industries. The advantages of S series of blowing machines: Low rejection rate, Stable running and Easy operation.

*Semi auto blow machine series as follow:

1, 2L machine 2 cavity

2, PC machine (1 cavity and 2 cavity)

3, PP machine (1 cavity and 2 cavity)

4, 5L machine (1 cavity and 2 cavity)

5, 8L machine (1 cavity and 2 cavity)

6, 10L machine 1 cavity

7, 20L machine 1 cavity

8, 30L machine 1 cavity

H series is automatic blow machine:

it can produce different shapes of bottles from 50ml to 30L, for mineral water, edible oil, soda, wine, cosmetics, lotion, detergent, pharmaceutical, pesticide, food cans, daily chemical, hot filling beverage and other fields industries. The advantages of H series of blowing machines: High speed, High performance and High configuration.

*Automatic blow machine series

As follow are small neck from 18mm to 48mm:

1, from 50ml to 1.5L, (2 cavity & 4 cavity)

2, from 1.5L to 2.5L (2 cavity & 4 cavity)

3, from 3L to 5L (1 cavity & 2 cavity)

4, from 7L to 20L (1 cavity & 2 cavity)

As follow are wide neck from 53mm to 200mm

5, 53mm – 90mm & Max. Diameter of bottle 105mm & 250ml to 1.5L (1 cavity & 2 cavity & 4 cavity)

6, 53mm – 105mm & Max. Diameter of bottle 120mm & 250ml to 2.5L (1 cavity & 2 cavity & 4 cavity)

7, 53mm – 127mm & Max. Diameter of bottle 140mm & 250ml to 4.5L (1 cavity & 2 cavity)

8, 53mm – 195mm & Max. Diameter of bottle 210mm & 250ml to 10L (1 cavity & 2 cavity)

9, 53mm – 195mm & Max. Diameter of bottle 450mm & 5L -20L (1 cavity)

*Key configuration of full auto machines:

1, From 1 to 6 sets servo system-Displacement servo & stretch servo & Preform feeding Servo & Clamping system by SIEMENS

2, All of the temp. adjustment by touch screen control by SIEMENS

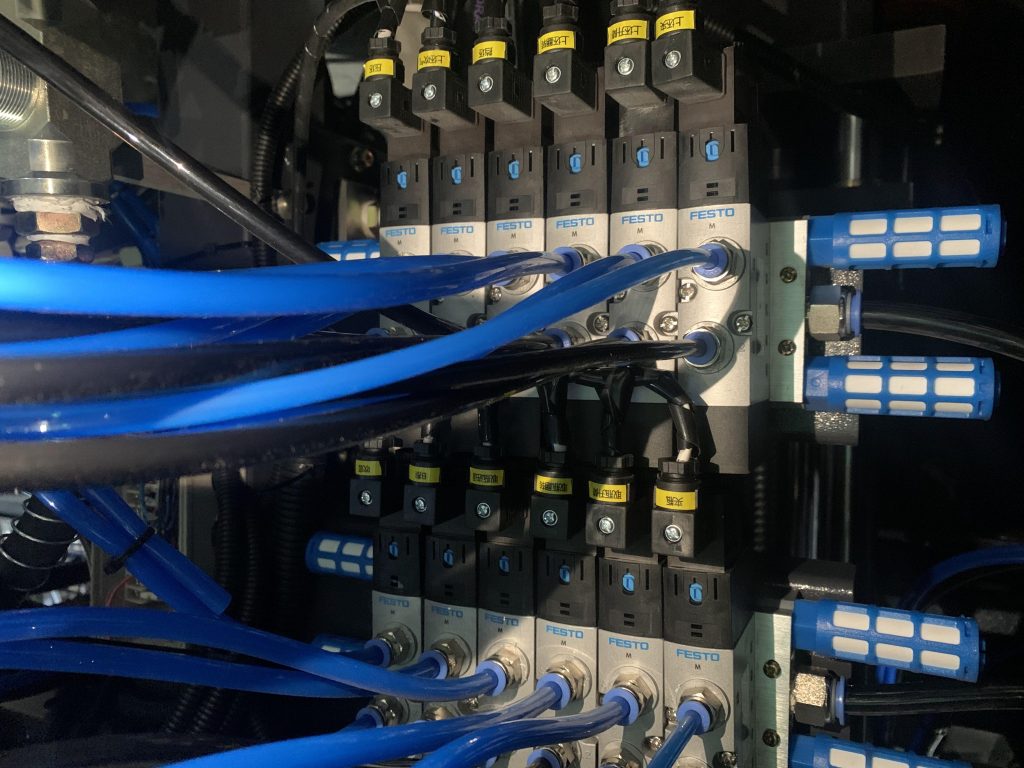

3, All of the action valves by FESTO

4, All of the cylinders by FESTO

5, All of the oil-water separators by SMC

6, All of the electrical components by SIEMENS

7, All of the servo motors and actuators by SIEMENS

8, High-pressure blow valve by FIM

9, PLC by SIEMENS

10, the Pathway for performing holder is stainless steel

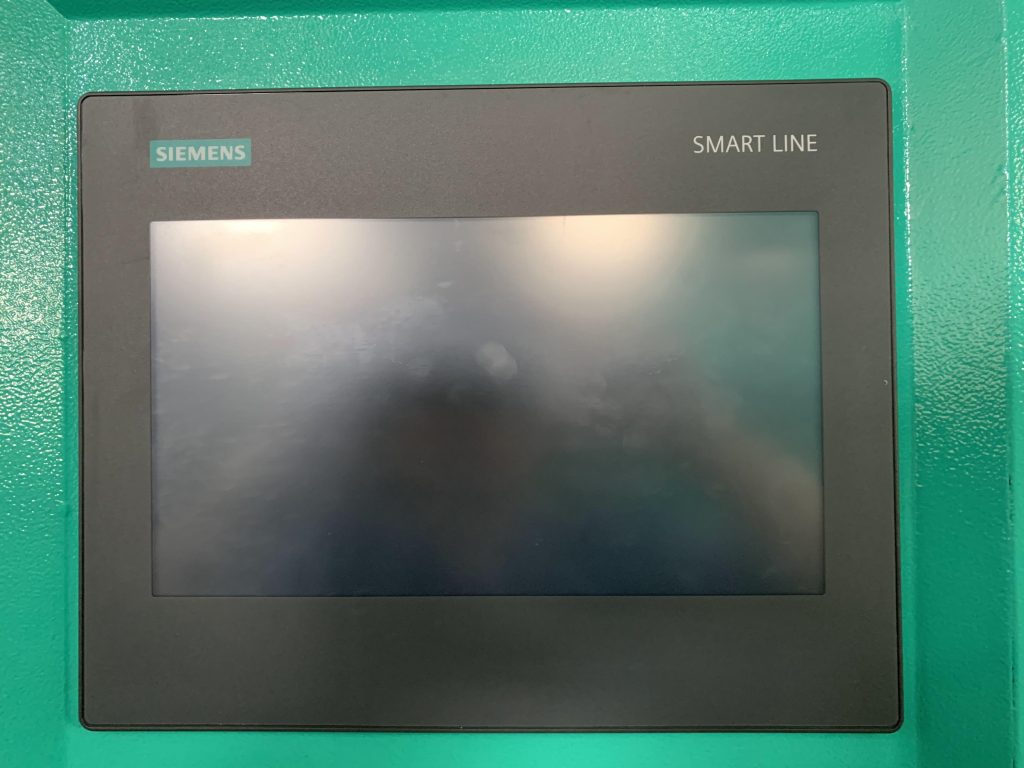

11, Touch screen by SIEMENS

F series is a full auto blow machine:

it can produce different shapes of bottles from 50ml to 30L, for mineral water, edible oil, soda, wine, cosmetics, lotion, detergent, pharmaceutical, pesticide, food cans, daily chemical, hot filling beverages, and other fields industries. The advantages of the F series of blowing machines: High speed, High performance, and High configuration.

*Full auto blow machine series- (standard models and high-speed models)

Neck from 18mm to 48mm

1, from 50ml to 1.5L, (2 cavity & 4 cavity & 6 cavity & 8 cavity & 9 cavity)

2, from 1.5L to 2.5L (2 cavity & 4 cavity & 6 cavity)

3, from 3L to 5L (1 cavity & 2 cavity & 3 cavity & 4 cavity)

4, from 7L to 20L (1 cavity & 2 cavity)

*Key configuration of full auto machines:

1, From 1 to 6 sets servo system-Displacement servo & stretch servo & Preform feeding Servo & Clamping system by SIEMENS

2, All of the temp. adjustment by touch screen control by SIEMENS

3, All of the action valves by FESTO

4, All of the cylinders by FESTO

5, All of the oil-water separators by SMC

6, All of the electrical components by SIEMENS

7, All of the servo motors and actuators by SIEMENS

8, High-pressure blow valve by FIM

9, PLC by SIEMENS

10, the Pathway for performing holder is stainless steel

11, Touch screen by SIEMENS

Configuration Of Electrical Componenets As Follow:

TOUCH SCREEN –SIEMENS

PLC – SIEMENS

SERVO MOTOR – SIEMENS

AC CONTACTOR – SIEMENS

3P BREAKER– SIEMENS

SIEMENS

More Detail for Machines

Corporate Perspectives

18mm to 48mm Preform Loading Machine: It is used for small neck, It is Stainless steel, the Size:2.0 * 1.35 * 2.55 M

53mm to 195 mm Preform Loading System: It is used for wide mouth Jar / PET Can, It is Aluminum Material, more stabilization and Smooth, the standard size 3M, it also can be made customized as your requirement 5M / 6M / 8M / 10M etc.

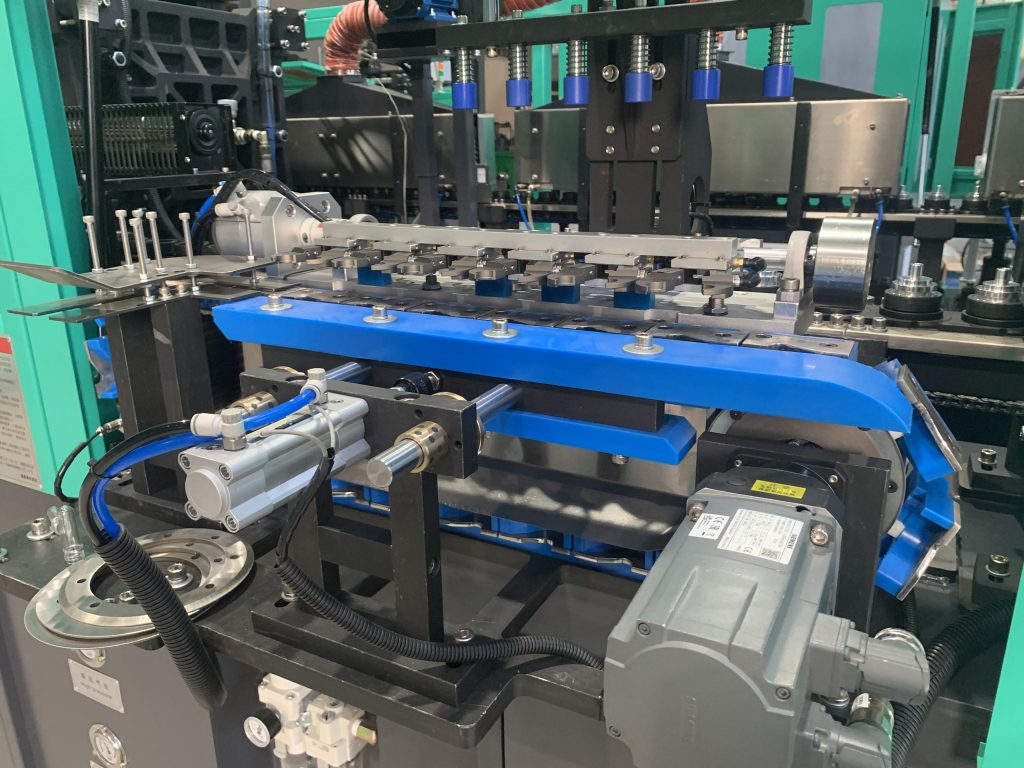

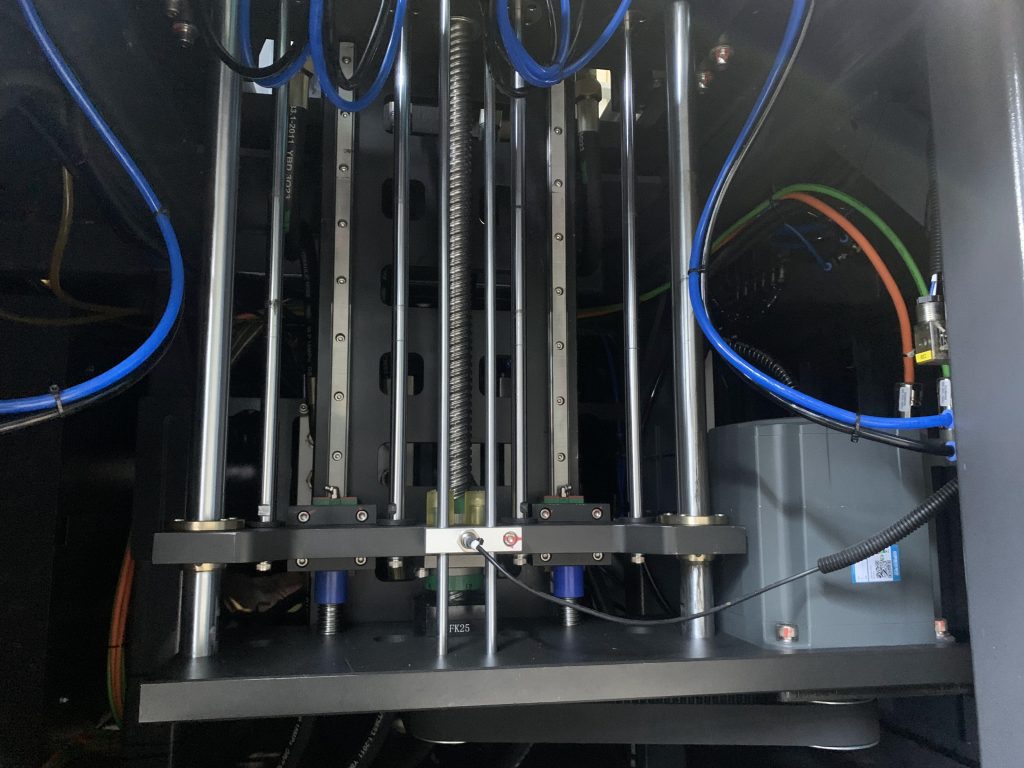

18mm to 48mm Preform Loading System: it has two models, one is SMC cylinder for automatic loading, another is Servo motors for automatic loading

Servo Loading

Cylinder Loading

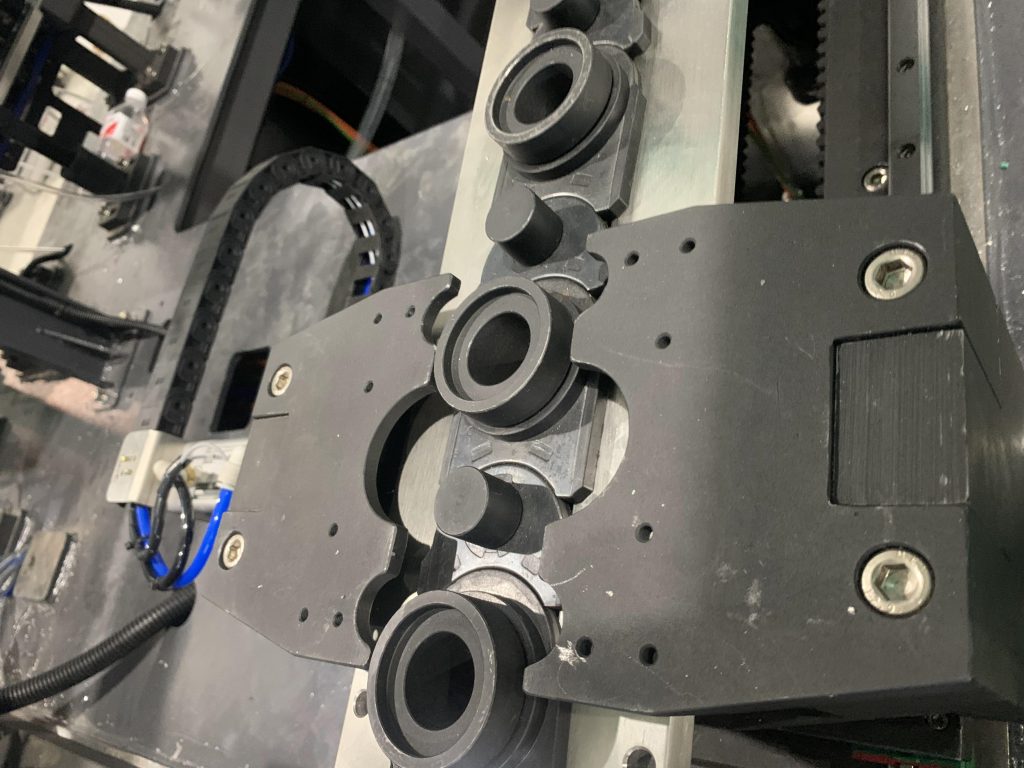

53mm to 195mm Preform Loading System: It has included three models as follow

2 sets SIEMENS sevo motor loading system & 1 set SIEMENS servo motor loading system & SMC cyinder Loading system

Double servo

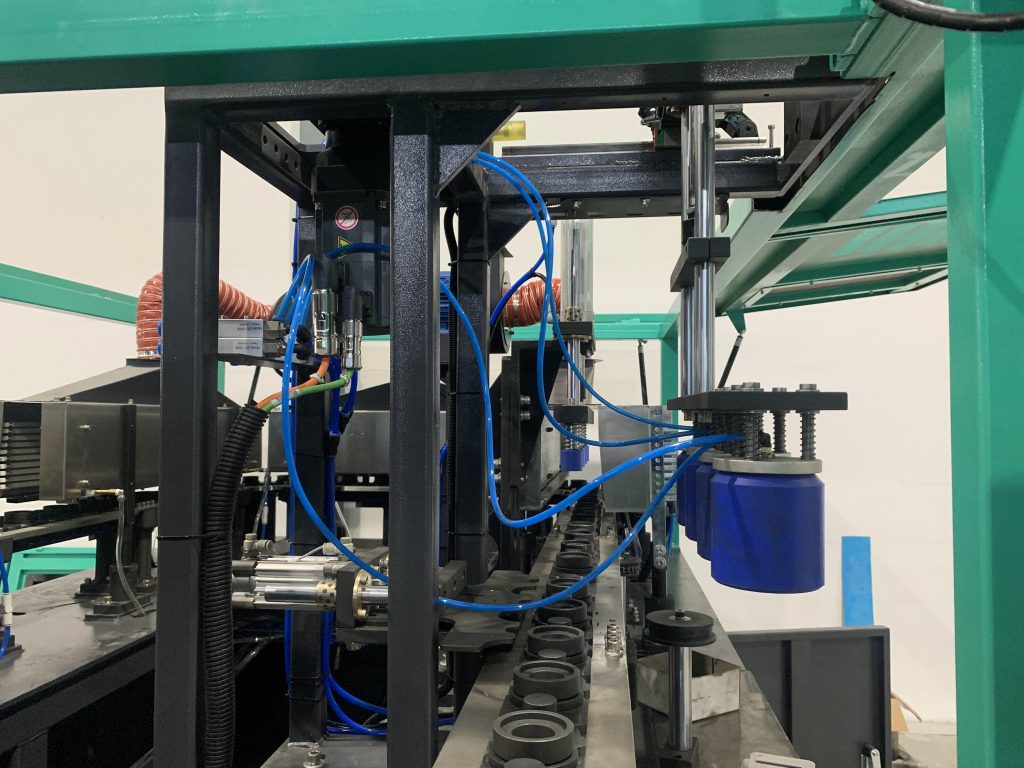

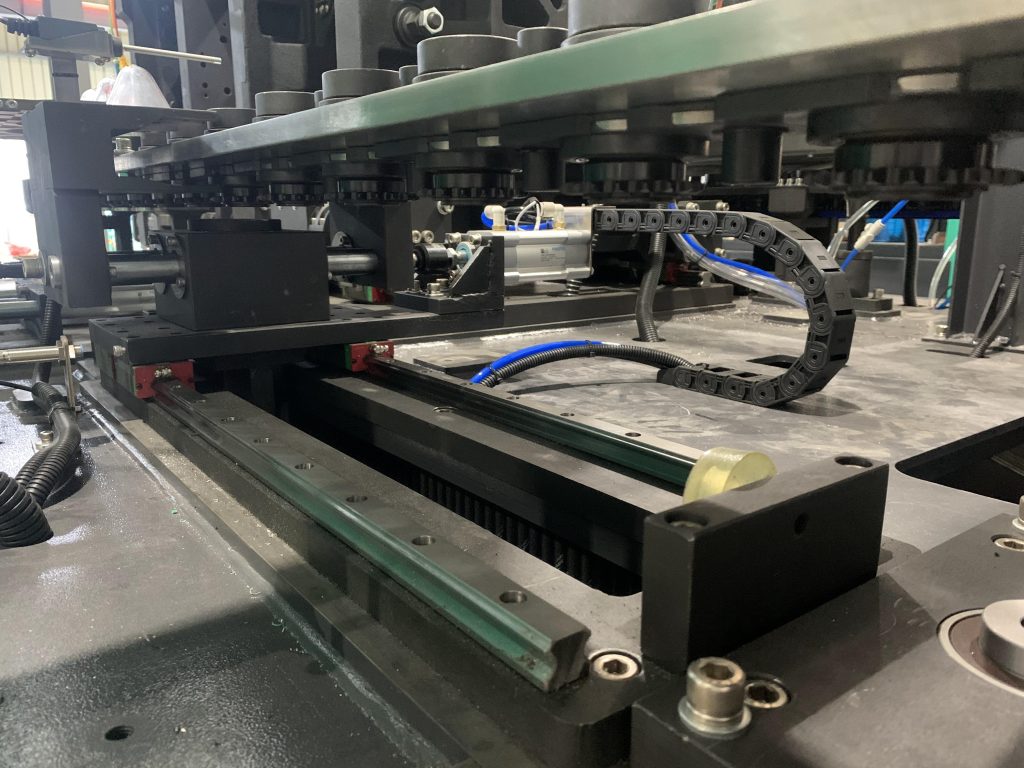

Chain System – N series

Chain System – O series

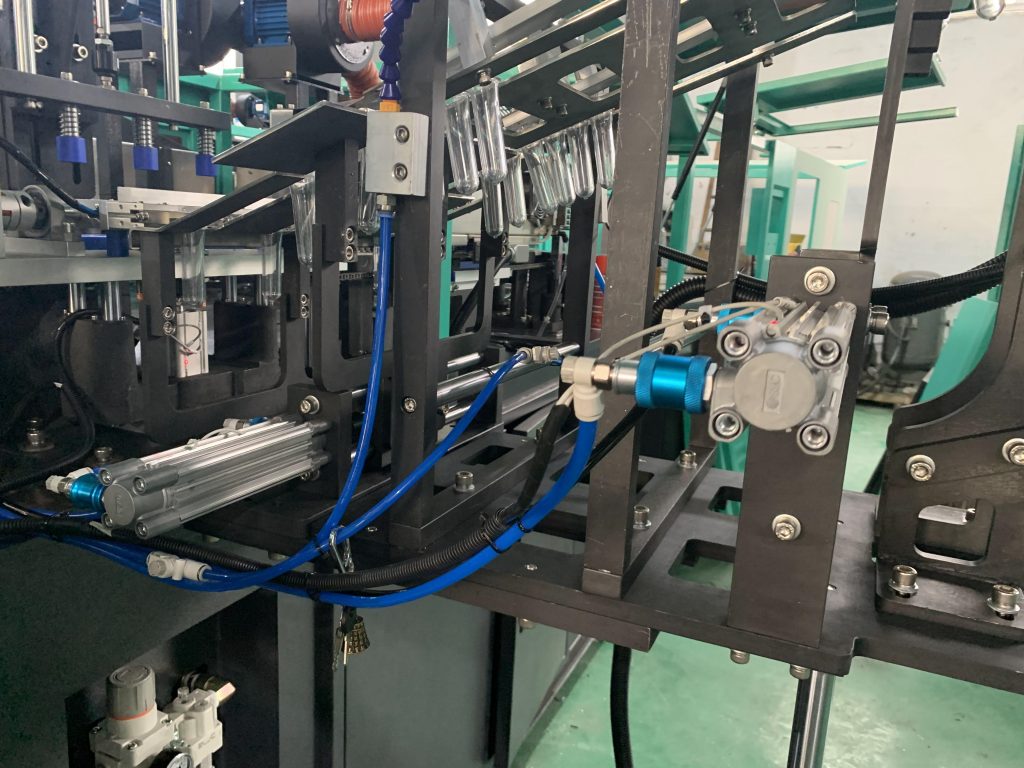

FESTO Cylinder & FESTO Action Valves

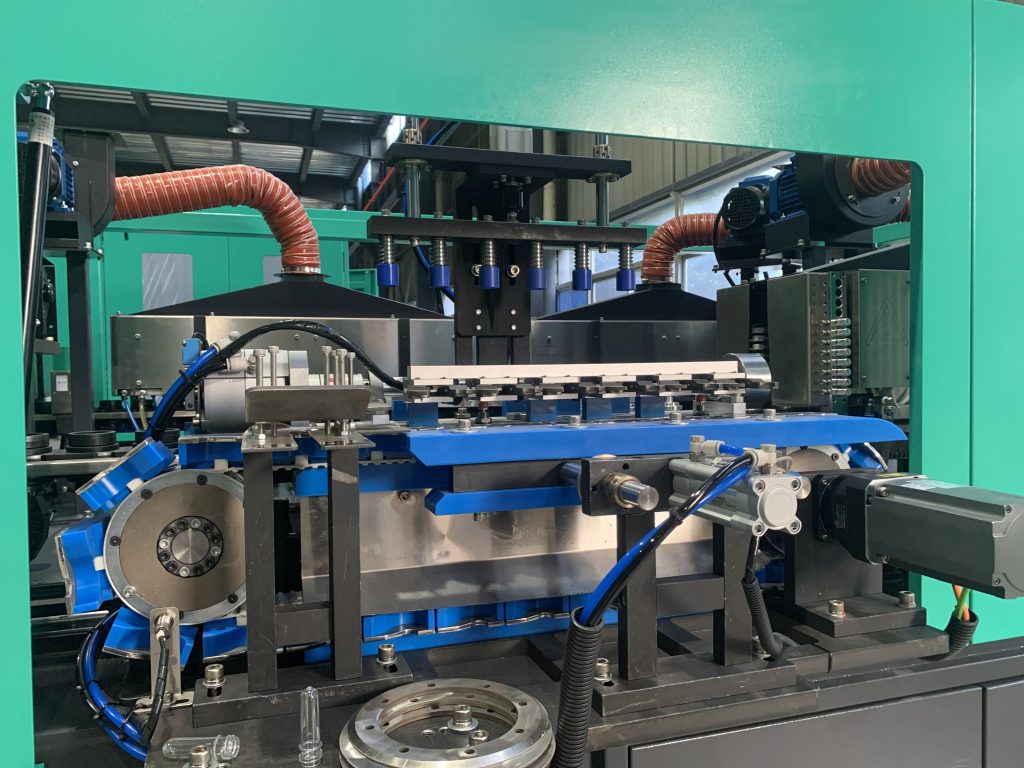

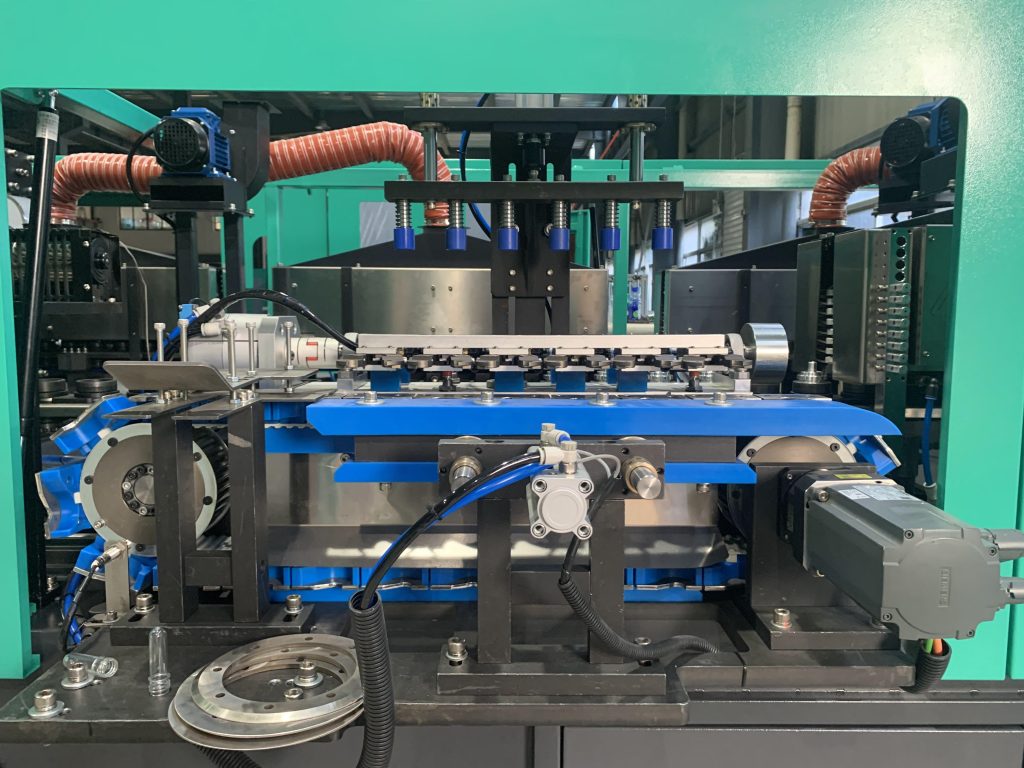

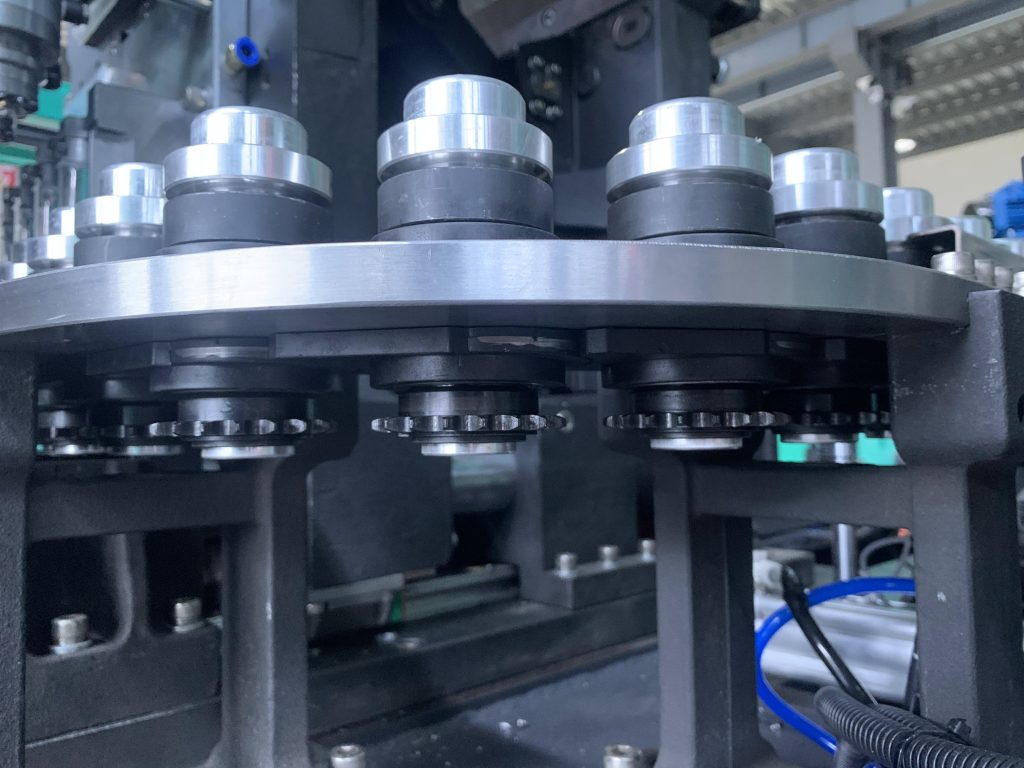

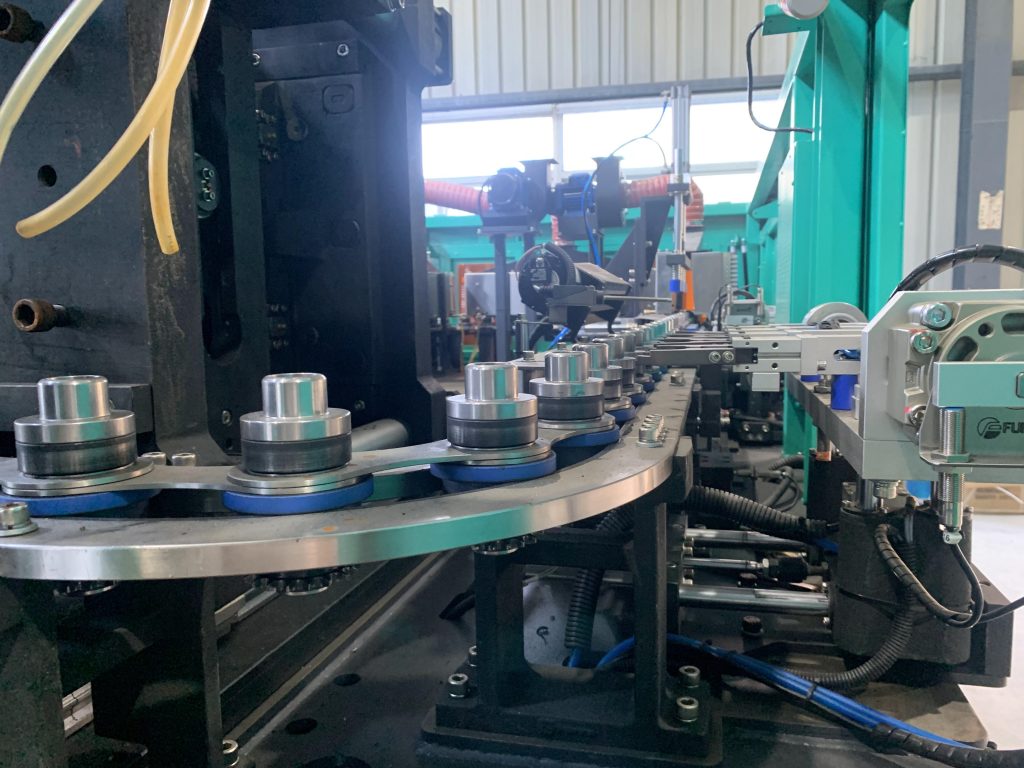

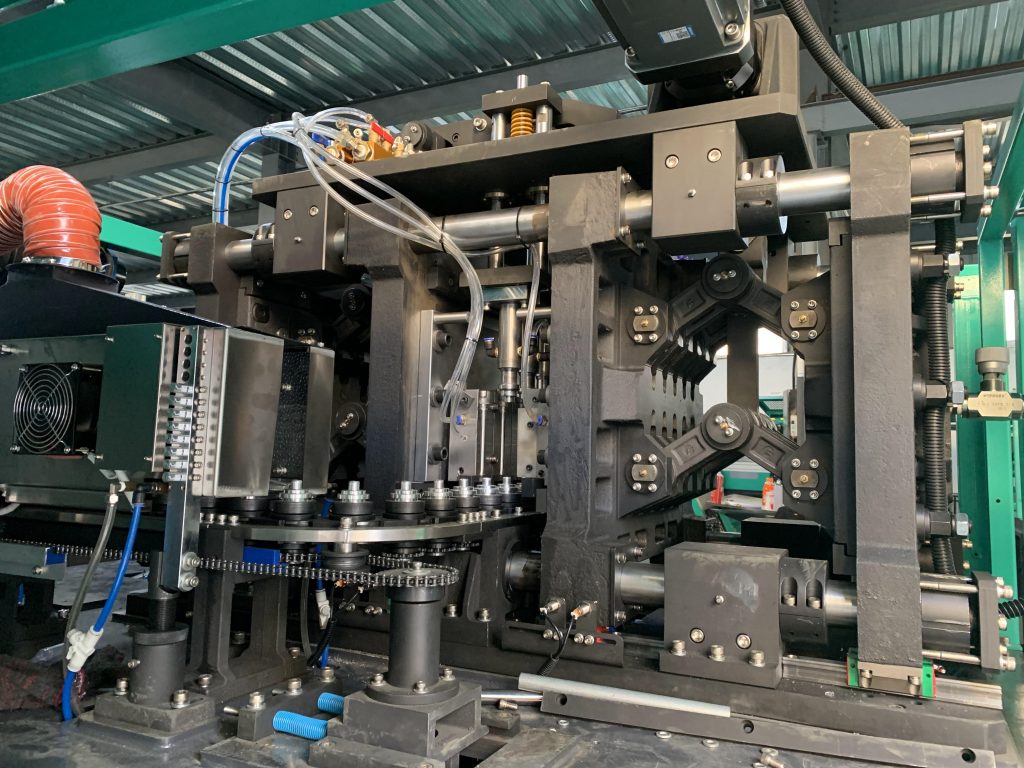

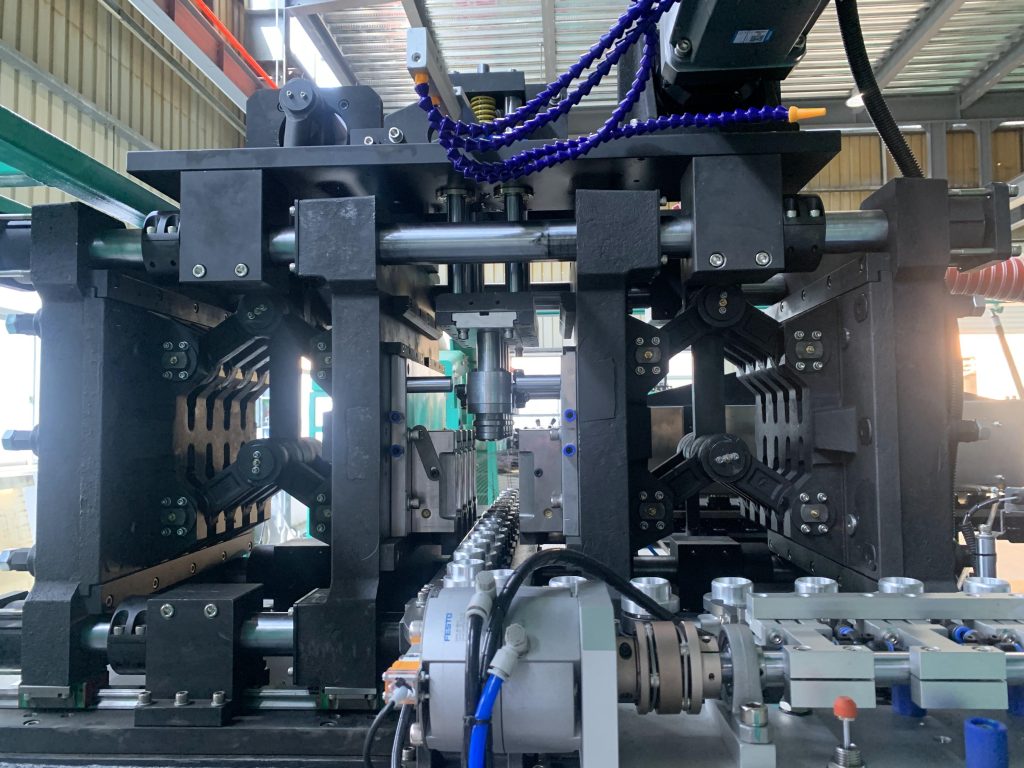

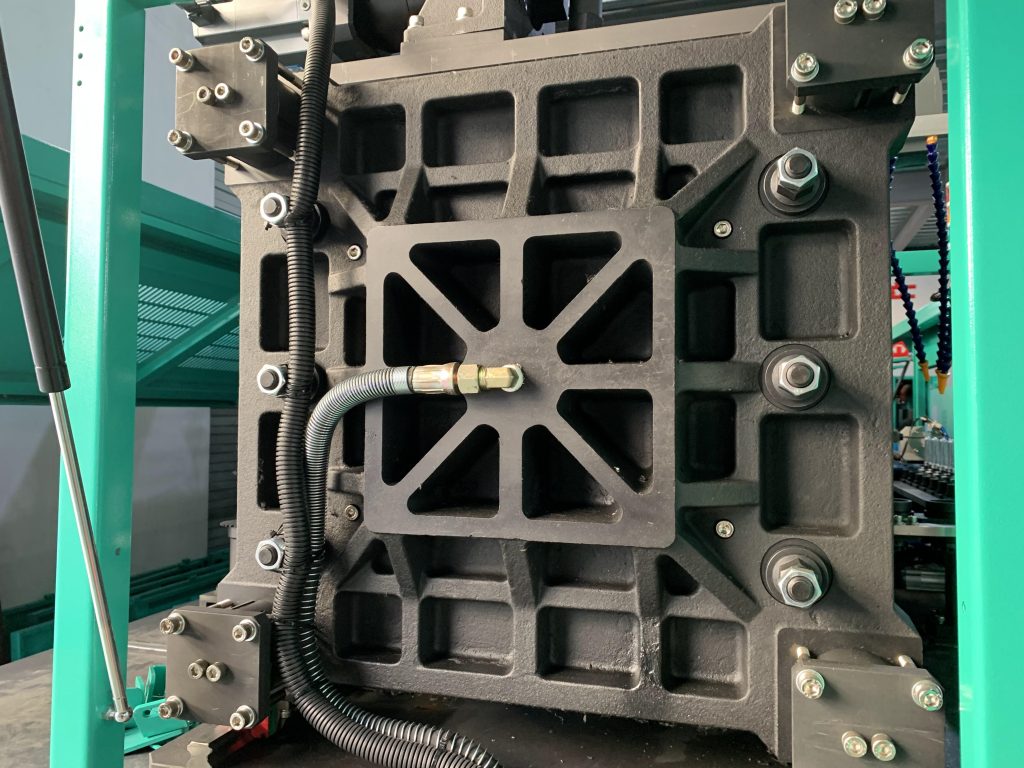

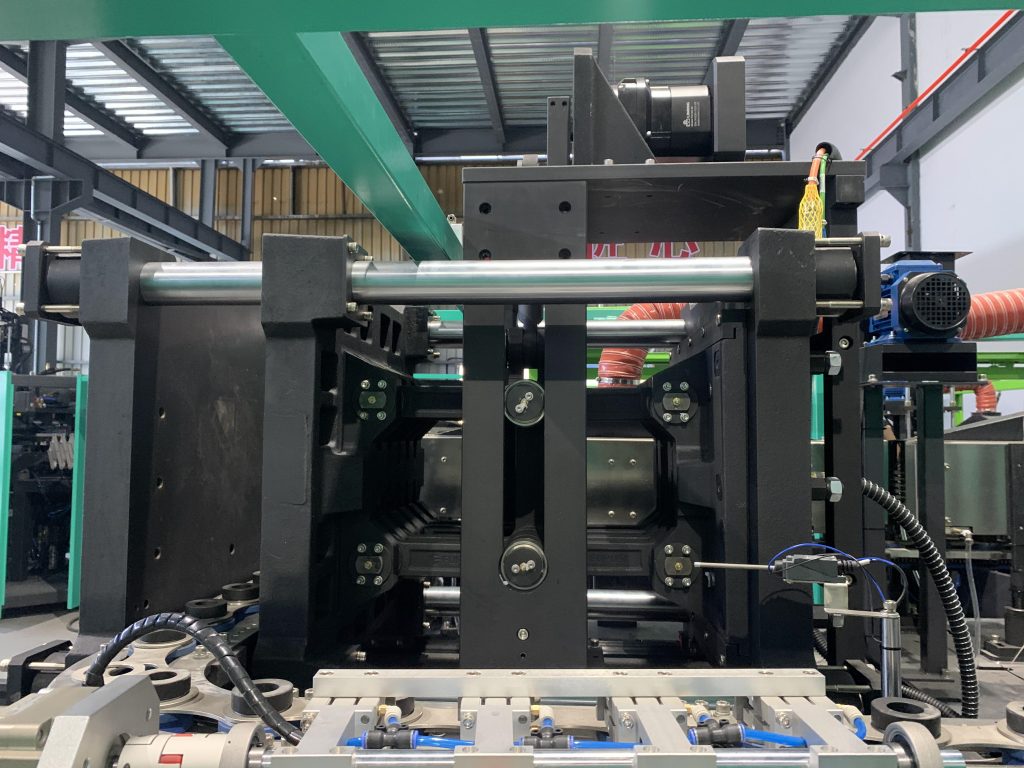

Double Servos – Mould Clamping System the cycle time is around 2.5-2.8s

Single Servo – Mould Clamping System, the cycle time is around 3-3.5s

Moving servo

Oven Zone & Stretch Servo System

Full automatic Blow Molding Machine

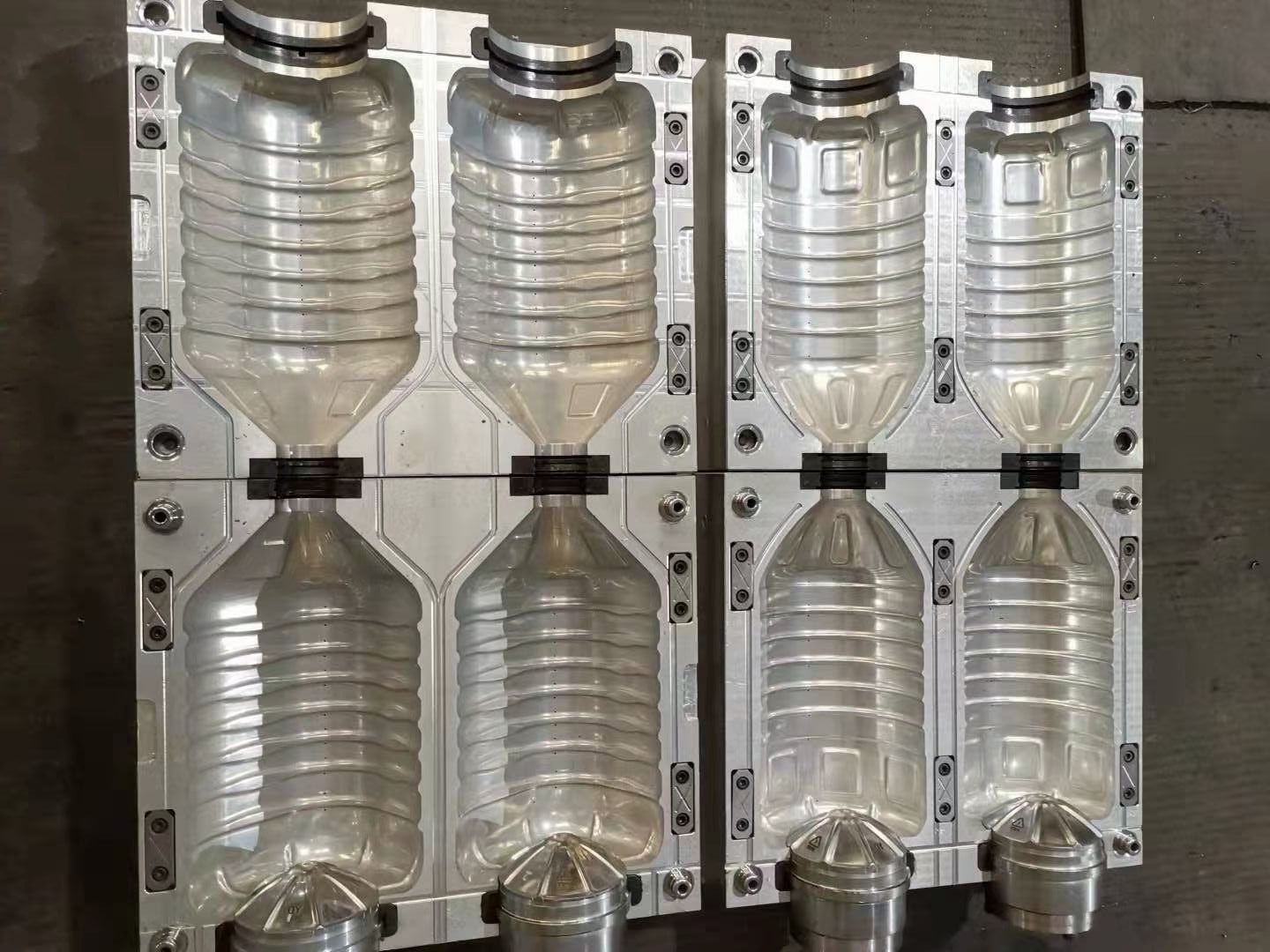

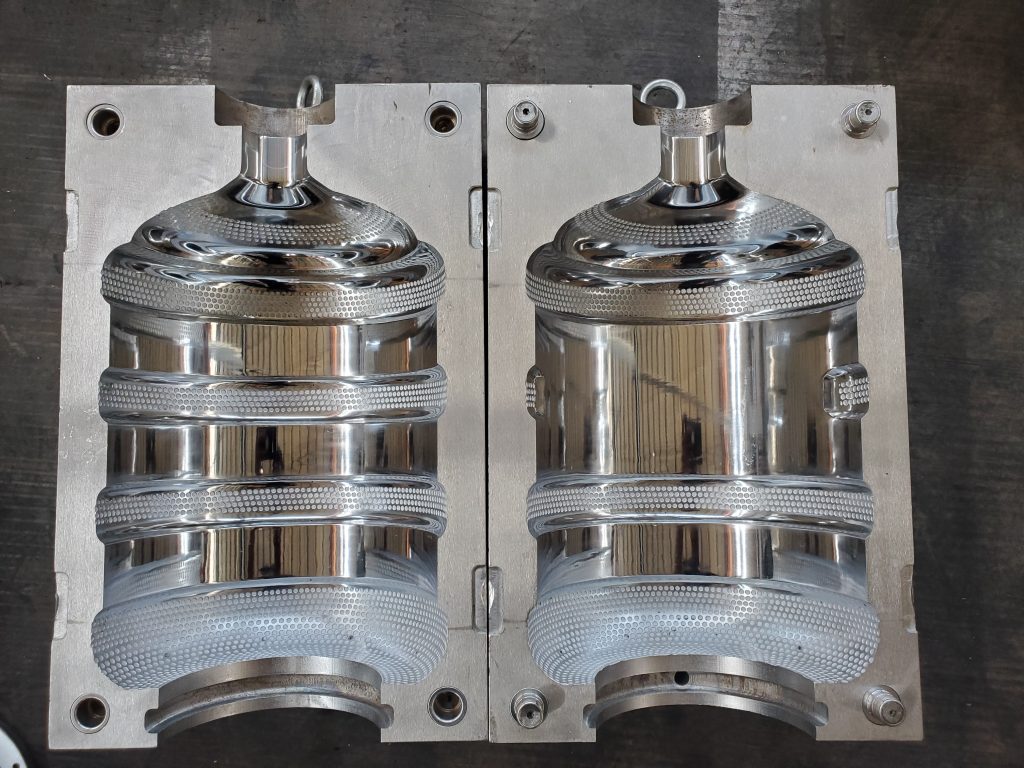

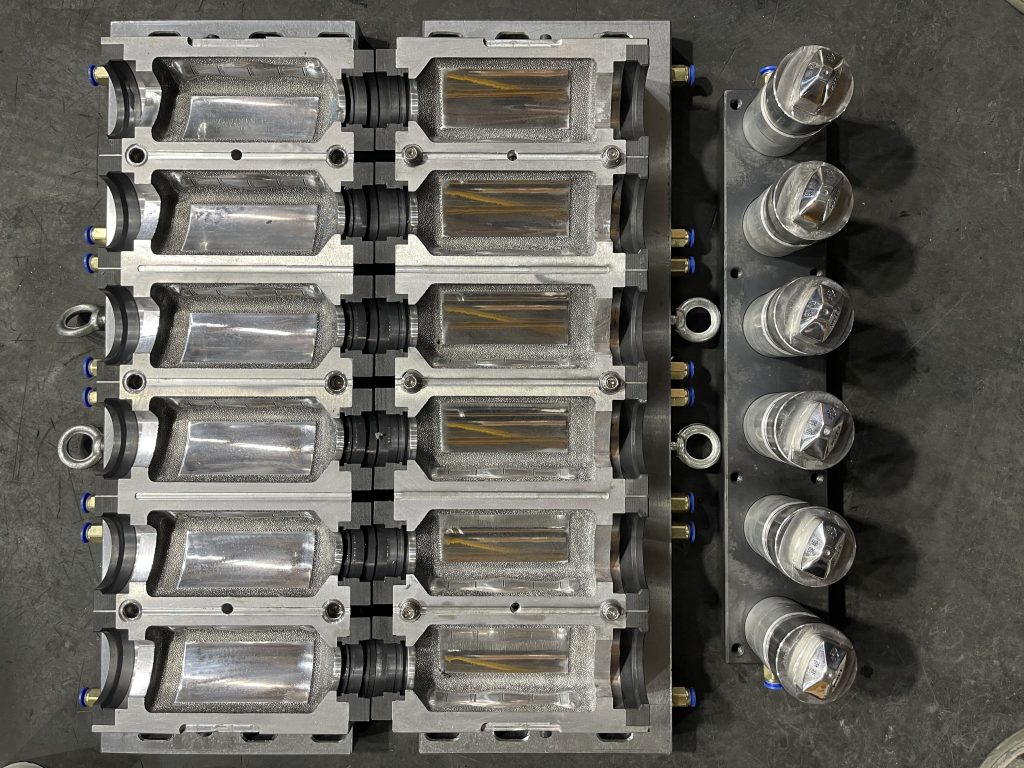

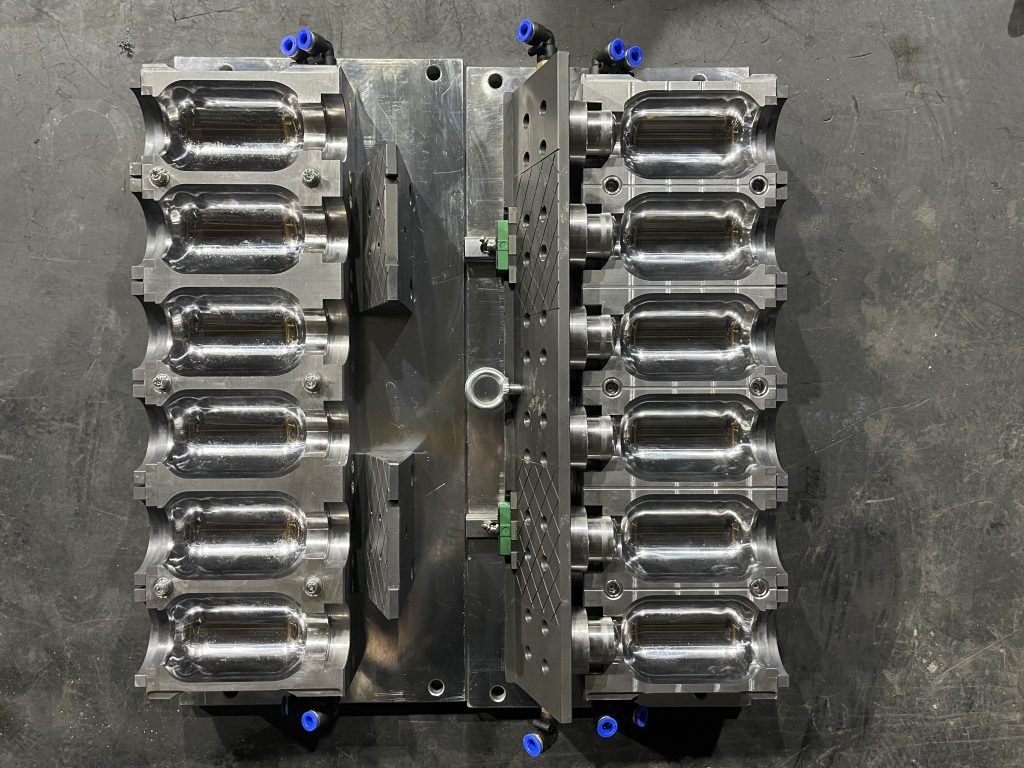

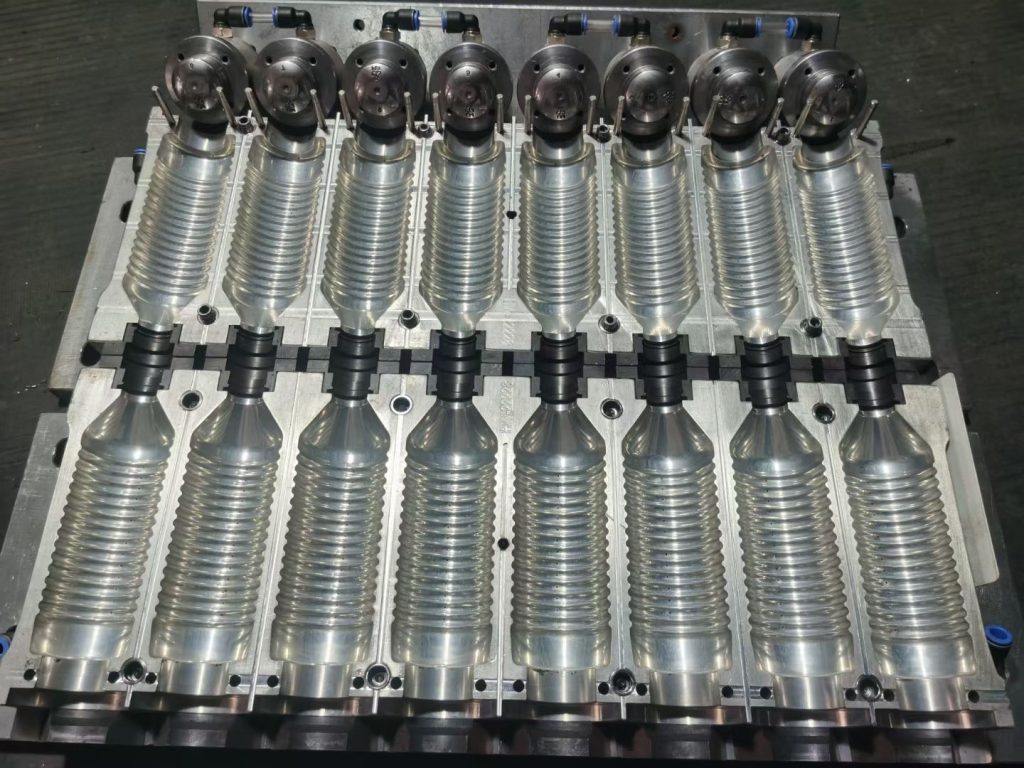

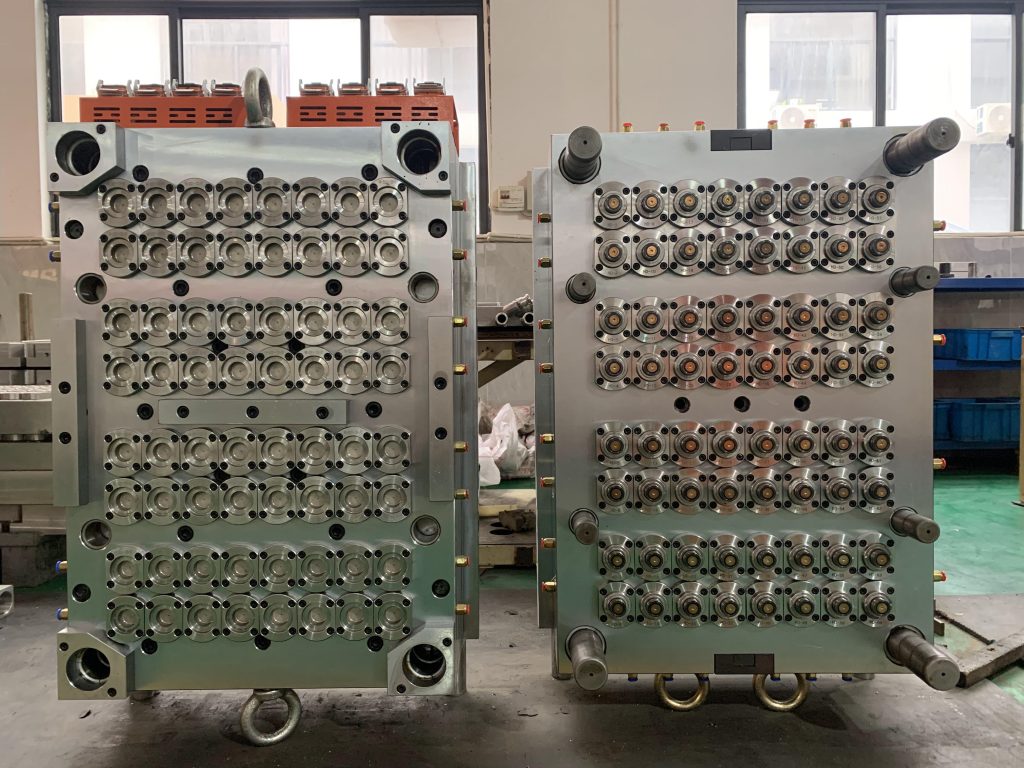

Photos of Molds

Warrantee & installing and Packaging and Shipping

*TRAINNING

The seller should train two or three operating men for free. (Travel and hotel are by buyer’s expenses.)

*INSTALLATION AND TEST

The buyer should place the machine in the right position and inform the supplier after the machine reaches the buyer’s factory.

The supplier will send the special men to test-run the machine until it is running in a normal state.

The buyer will bear the come-to-return air tickets, accommodation, hotel, etc the customer’s side.

The buyer will pay USD 140/day/person as technician labor cost when he leaves the factory until he leaves the client’s plant.

*GUARANTEE

Our guarantee is valid for a period of 18 months.

If the malfunction is caused by the machine’s self-quality, we will troubleshoot it for free.

*Delivery time

Around 45-60 days after receiving prepayment

*Delivery Terms

Ex Factory & Ningbo Port

*Payment Terms

40%TT as deposit, 60%TT balance will be paid before delivery

*Packaging

Export Standard Seaworthy Packing in Strong Film and wooden