Taizhou Fupusi Machinery Co.,Ltd.

John Tao as the president of Taizhou Fupusi Machinery Co., Ltd. who has more than 15 years experience in plastic bottle industry field, he is focus on improving the quality of the machines and after-sales system

Machine maintenance and operation

catalog

I. Safety 1

I. Machine safety system: 1

II. Operator safety precautions: 2

III. Safety precautions for all workers: 3

IV. Precautions for air pressure system: 7

V. Maintenance and inspection safety: 10

VI. Safety precautions for management personnel: 12

VII. Legal regulations: 13

VIII. Material and smoke issues: 14

IX. Fire extinguisher: 15

X. Dismantling machine: 15

II. Operation precautions: 16

I. Precautions before machine operation: 16

II. Precautions before and during operation: 18

III. Inspection: 19

III. Install 22

1、 Machine installation: 22

IV. Operation and adjustment: 32

I. Pre startup check: 32

- Photoelectric sensors on the feeding track: 32

- Pre molding photoelectric sensor: 32

- Specific discharge limit switch: 33

- Electrical components: 33

- High pressure air: 33

- Machine: 34

- Mold: 34

- Other 34

II. Adjustment before startup: 35 - Feeding system: 35

- Transportation system: 36

- Heating device: 36

- Emission system: 37

- High pressure air: 37

III. Opening steps: 38

IV. Control panel: 39 - Power selector: 39

- Main interface in automatic mode: 40

V. Troubleshooting: 45

Attention: Regardless of any abnormal situation, the operator should first press the emergency stop button to stop the machine from running. 45

When the machine runs abnormally, the HMI (control panel) screen will display an alarm message indicating the abnormal situation. 45

(1) Feed (alarm information): 45

(2) Unloading (alarm message): 45

(3) Mold (alarm information): 46

(4) Transmission (alarm message): 46

(5) Slide (alarm message): 47

(6) Telescopic pole (alarm message): 47

(7) Guide rail (alarm information): 48

(8) Oven (alarm information): 48

(9) Abnormal cooling warning (alarm message): 49

(10) Pre formed spindle track error: (alarm message): 49

(11) Servo motor (alarm information): 49

(12) Manual operation error (alarm message): 50

(13) Lamp holder abnormality: 50

VI. Emergency stop: 51

VIII. Closing steps: 57

VI. Mold installation: 58

I. Precautions for mold installation: 58

II. Precautions for replacing each component: 58

VII. Maintenance and lubrication: 62

I. Maintenance and lubrication: 62

II. Cleaning: 63

III. Daily maintenance: 64

IV. Monthly maintenance: 66

V. Seasonal maintenance -1500 hours: 68

VI. Annual maintenance -6000 hours: 70

VII. Update on infrared lights: 71

VIII. Lubrication: 72

IX. Location of sensor: 76

VIII. Appendix 81

I. Security

I. Machine security system:

To protect the operator, fixed plates have been added around the heating furnace, and the heater connectors are kept away from direct contact with the operator.

This machine has already been installed with a thermometer. In any abnormal situation, the alarm will issue a warning signal.

3. This machine adopts a high-pressure compressor, and all accessories and pipelines should use high-pressure resistant components.

(1) Operating circuit air pressure: 7 kgf/cm2.

(2) The high-pressure tank should be equipped with a safety valve. If the assumed pressure exceeds 40 kgf/cm2 (maximum), the safety discharge will automatically operate.

4. This machine has a dedicated grounding device and grounding plate. The diameter of the grounding connection should exceed or comply with the specifications specified by the company.

5. Three emergency stop buttons are installed on the operation panel and side platform. Before operation, ensure that the emergency button is functioning properly.

6. The torque limiter is installed inside the machine to avoid any emergency situations

II. Safety precautions for operators:

During the operation, do not put your hands into any mechanism. (including: all institutional execution, molds, and operation panels)

2. Do not place residues or tools on the machine platform to prevent them from falling into the machine. In addition, operators are not allowed to climb the workbench to prevent slipping.

3. During the operation, it is not allowed to enter the safety door.

Before turning on the power again, please ensure that all workers and tools are away from the machine (e.g. after installation, adjustment, maintenance, or inspection, etc.)

Caution: If the precautions in the operation manual are not followed, the operator may be injured and/or easily damaged or the machine may be damaged.

III. Safety precautions for all workers:

(Provided: Operator, Manager, Quality Control, Electrical and Power)

Maintenance technicians

1. Whenever the machine needs maintenance or repair, be careful of the items under your feet during the climbing process. In addition, for safety reasons, it is important to wear appropriate clothing and safety shoes to avoid slipping. Maintain a safe posture during operation to prevent falling or slipping.

The vibration of the moving parts of the machine during operation can cause slipping and falling. To avoid machine chaos or operator injury, climbing is strictly prohibited during operation.

3. When the operator enters the machine for maintenance, inspection, cleaning, and troubleshooting, ensure that the machine is turned off during the process.

Experienced technicians or workers who have received comprehensive training can operate, maintain, or repair machines. In addition, do not operate or repair machines without understanding them.

5. When operating, be sure to wear recommended operating clothing and non slip shoes to prevent falling objects from hitting your feet. Don’t wear clothes that are too loose. If your hair is too long, tie it up or wrap it with a seat belt to avoid getting caught in the machine in dangerous situations.

During the operation, no one is allowed to enter the machine.

7. Whenever operating with high air pressure, ensure that the mold and lower mold are restored to their original positions.

8. During operation, all operators should wear masks to avoid high-pressure air emissions from their noses.

9. Machine operators must carry earplugs

| precautions |

| Before operation, ensure that the air pressure supply is stopped and the pressure gauge pointer should be 0 kgf/cm2. In situation (1), if the mold, robot, or stretching rod needs to move, a main power supply should be provided for forced execution. After the operation is completed, the air pressure should be set to the “off” position. Be sure to put the mold, lower mold, and robot back in their original positions. |

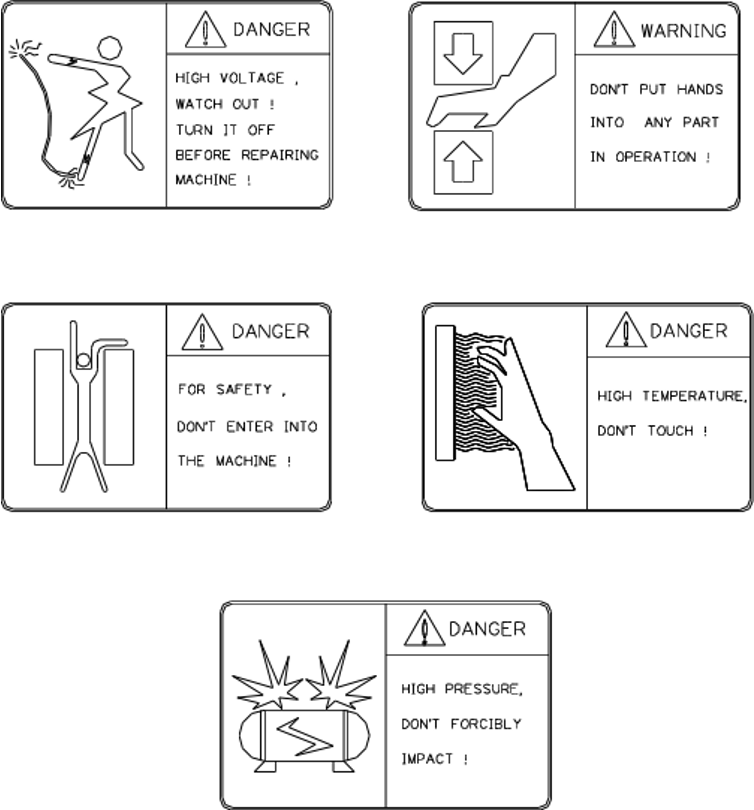

The following safety alert notifications should be posted on the machine

Before operating the machine, please read the operation manual.

During maintenance of electrical cabinets, operation panels, terminal boards, heating furnaces, etc., the main power supply should be cut off.

Before operation, ensure that the emergency stop device is working properly.

4. All peripheral equipment, bolts, nuts, and shafts of the stretch blow molding machine are in metric system.

When installing and repairing molds, it is necessary to place safety blocks for all moving parts and confirm that they still exist before operation. Maintenance requires two or more technical personnel.

6. It is necessary to check whether the gas storage tank, safety valve, pressure gauge, regulator and other equipment are leaking or experiencing abnormal conditions. Regularly inspect according to the inspection schedule.

7. Regularly check whether the bolts of the closed mold cylinder, stretch blow molding cylinder, etc. are loose?

When repairing or installing the stretch blow molding machine, the power should be disconnected and the motor turned off. Two or more technical personnel are required before operation.

9. Do not touch the mold and rotating parts to avoid injury.

When repairing, maintaining, or adjusting the heating furnace, please disconnect the power first and wear insulated gloves.

11. When installing molds using bridge cranes or lift trucks, be sure to wear safety shoes and protective belts.

After operation, the power supply of the peripheral facilities of the stretching and blowing machine should be cut off.

When the machine stops running, the pressure and air pressure of the operating circuit should be adjusted to 0 kgf/cm2.

14. Do not replace or dismantle safety protectors and safety doors at will to avoid accidents.

15. Safety protectors must be installed during operation.

16. The air pressure pipe should be inspected regularly. If there is any breakage or abnormal situation, the vehicle should be stopped immediately to replace the parts.

17. The lubricants and tallow used on the sliding or rotating surfaces of the stretch blow molding machine shall comply with the approval of the US Food and Drug Administration.

18. The lubricating oil of the peripheral equipment of the machine should be replaced regularly.

19. The structure, mold, and peripheral equipment of the stretch blow molding machine shall not be replaced; Otherwise, the manufacturer shall not be held responsible for the modified results.

20. The wiring and pipelines of the peripheral equipment of the stretching blow molding machine should be checked regularly. If any abnormal situation is found, please stop running and contact the manufacturer for repair as soon as possible.

21. The replacement parts of the stretch blow molding machine should be labeled with the original brand. 22. The circuit of the stretch blow molding machine should be regularly checked for electrical leakage. If there is a leakage, please stop running and disconnect all power sources to check the cause of the leakage.

IV. Precautions for air pressure system:

High pressure refers to compressed air under extremely high density and pressure. Improper operation caused significant damage. Operators or peripheral devices will be in a dangerous state. Therefore, please remember the following precautions:

When replacing air system components, be sure to disconnect the air source of this machine and completely exhaust the air in the air system.

2. The preset safety valve and the pressure of the gas storage tank shall not be changed arbitrarily.

3. Keep the gas storage tank free from any external attack or impact.

When replacing the mold, it is necessary to exhaust the air in the pneumatic system to avoid danger. (Open the pressure discharge gauge to reduce the pressure.)

5. Long term closure of gas storage tank:

(1) Release pressure at a rate of 0 kgf/cm2

(2) The interior of the gas storage tank should undergo anti-corrosion treatment.

6. When reusing the air storage tank and pressure system, pay attention to the bellows:

(1) Firstly, check the low pressure condition and do not raise it to high pressure all at once.

(2) Before applying maximum high pressure, please check the air pressure system in advance.

7. Do not remove the exhaust muffler of the air system to avoid noise from pressure air emissions.

When performing maintenance or repair, be sure to open the vent valve by hand and lock it until the pressure gauge reaches zero kgf/cm2.

9. Conduct the following regular inspections: Daily inspections:

(1) Check the pressure gauge to ensure that the fuel tank is used within the specified range.

(2) Visual inspection and listening to detect air leaks in the air system, including fuel tanks, hoses and pipes, joints

(Connectors), valves, and cylinders.

(3) Check for flattened hoses and loose connections in the air system.

(4) Use a drain valve to drain the water from the water tank.

Attention: If the pressure is higher than the set value, the safety valve on the blow tank will discharge the excess pressure.

Weekly inspection:

(1) Ensure that all bolts and nuts on the air solenoid valve and pressure reducing valve are tightened.

(2) Check and clean the exhaust muffler.

Every six months:

(1) Check the accuracy of the pressure gauge of the gas storage tank and calibrate it.

Annual inspection:

(1) Check the air storage tank itself, valves, instruments, pipelines, and joints (connectors) for leaks with soapy water

(2) Check the function of the safety valve above the specified pressure

(3) Check if there is corrosion on the fuel tank wall

V. Maintain and inspect safety:

Attention: When performing maintenance, be sure to follow the regulations, otherwise the machine and peripheral devices are easily damaged.

When performing maintenance or repair, be sure to cut off all power sources and hang a “Do Not Use” signal. Use an electricity meter to check if there is a power source “on”. Before starting work, open the drain valve by hand, ensure that the pressure gauge is 0 kgf/cm2, and lock the intake valve. If the machine needs maintenance, it must be hung on a “maintenance” billboard.

The set pressure of the exhaust valve within the air pressure is adjusted by the manufacturer. If the pressure gauge exceeds the high pressure specified by our company, the service life of this machine will be shortened.

In order to protect the safety of operators, the movable parts of the machine are designed with safety doors and heating furnace protective covers. Don’t take it away casually. During operation, the safety door and electrical control cabinet door must not be opened and should be checked daily.

When adjusting the air pressure system or template, be careful not to be scratched by the chuck.

5. Pneumatic components used on the machine, such as air storage tanks, air pressure regulators, safety valves, cylinders, pipeline connections, and high-pressure pipelines. When replacing, reduce the high voltage to 0 kgf/cm2 and confirm that the template has been separated. After operation or regular maintenance, soap water should be applied to the composite components to check for air leaks. Check the safety valve of the pneumatic system every six months.

When the stretching blow molding machine or electrical system needs maintenance or repair, be sure to keep the power switch in the “off” position. If there is a key device, please lock it to ensure safety.

7. Check for water leaks at all times, especially electrical components, and do not allow water connections. Molds, heating furnaces, etc. all require water. When maintaining or repairing, it is necessary to check whether the connecting components are leaking water? When disassembling or replacing the mold, be sure to completely drain the water.

8. Refuel or replace the stretch blow molding machine to ensure it is in a stationary state.

9. Use standard tools for maintenance, repair, and inspection, such as bolts and screws that should be securely fastened with appropriate torque.

10. The parts, consumables, watches or instruments of the stretch blow molding machine should be inspected regularly.

When conducting electrical maintenance or repairs while powered on, it is essential to use insulation materials or equipment (such as clothing, shoes, gloves, and safety helmets) and insulation tools (such as screwdrivers and clips) for protection. Remove metal items such as rings, bracelets, necklaces, etc. and operate safely. Two people participate in maintenance and repair to ensure safety.

When resting, be sure to cut off the main switch power supply.

13. Do not touch electrical equipment with wet hands.

14. The water and air pipes in the factory should meet the specifications of our stretch blow molding machine. In addition, pressure standards and equipment should comply with the prescribed specifications. High pressure pipelines and regulator joints must comply with high pressure specifications, pressure resistant materials, and structures.

15. Electrical equipment and related wiring should meet the following requirements:

(1) Before operation, appropriate grounding plates and grounding connectors should be connected to the designated location or body.

(2) Use fuses of the correct capacity.

(3) The capacity of relevant electrical components should comply with the specifications for insulated cables.

10. The parts, consumables, watches or instruments of the stretch blow molding machine should be inspected regularly.

When conducting electrical maintenance or repairs while powered on, it is essential to use insulation materials or equipment (such as clothing, shoes, gloves, and safety helmets) and insulation tools (such as screwdrivers and clips) for protection. Remove metal items such as rings, bracelets, necklaces, etc. and operate safely. Two people participate in maintenance and repair to ensure safety.

When resting, be sure to cut off the main switch power supply.

13. Do not touch electrical equipment with wet hands.

14. The water and air pipes in the factory should meet the specifications of our stretch blow molding machine. In addition, pressure standards and equipment should comply with the prescribed specifications. High pressure pipelines and regulator joints must comply with high pressure specifications, pressure resistant materials, and structures.

15. Electrical equipment and related wiring should meet the following requirements:

(1) Before operation, appropriate grounding plates and grounding connectors should be connected to the designated location or body.

(2) Use fuses of the correct capacity.

(3) The capacity of relevant electrical components should comply with the specifications for insulated cables.

16. When connecting the power supply after maintenance and repair, confirm that the connection is good. If any problems or errors occur during maintenance and repair, please ensure to resolve them before connecting the power supply.

VI. Safety precautions for management personnel:

1. All live working personnel should receive education on safety content.

2. Machine maintenance administrators should possess all relevant knowledge and training.

To ensure safety, it is recommended to have at least two people participate in operation and maintenance.

4. According to our safety requirements, use in conjunction with other accessories. Please do not replace molds or peripheral devices at will.

To ensure safe and efficient operation, the machine should be inspected at least once every five years after debugging.

To ensure operational safety, safety devices or safety valve isolators must not be removed or replaced during any normal operation.

VII. Laws and regulations:

The operation of this machine is subject to laws and regulations such as high-pressure gas treatment, fire protection laws, and worker safety and health regulations. It is necessary to carefully read these laws and regulations and seek advice from organizations related to the safe handling of high-pressure gases and other hazardous substances, as well as authoritative industrial accident prevention associations.